reduce your cost per cut

Bahco's carbide tipped band saw blades are the industry leaders in performance and productivity

Carbide tipped bandsaw blades deliver improved performance when cutting special alloys (aluminium, titanium, stainless steel, Hastalloy, Inconel and Waspalloy), difficult and abrasive materials, or when working with large, hard-to-cut pieces.

3860

Multi-Chip & Triple Chip Unset Carbide Tipped - TMC & TCL

TMC Developed Specifically for Cutting Titanium Alloys

Performs extremely well cutting Titanium solids and blocks, 718 and other high temperature Alloys and aluminum.

- Special tooth geometry designed for Titanium applications

- Unset teeth provide a superior surface finish, long life and eliminate secondary operations

- Special grade of carbide tooth material provides maximum life and cutting performance

- Tooth tips are fine ground to give a sharp edge essential for cutting Titanium

The tooth design is a 10° positve rake angle and is used for our unset carbide blade. It excels in difficult to cut alloys on stable machines.

Triple-Chip Unset Carbide Tipped - TCL

Multi-Chip Unset Carbide Tipped - TMC

Blade Width (Inches)

1-1/2 x .050

1-1/2 x .050

2 x .062

2 x .062

2 x .062

2-5/8 x .062

Teeth per inch

1.4/2

2/3

1/1.25

1/4.2

2/3

1/1.25

TMC Developed Specifically for Cutting Large and High Temperature Alloys

- High heat resistance allows high speed cutting even in large solids.

3860 Triple-Chip Unset Carbide Tipped TCL

Blade Width (Inches)

1-1/2 x .050

1-1/2 x .050

2 x .063

2 x .063

2-5/8 x .063

2-5/8 x .063

Teeth per inch

1.4/2

2/3

1.4/2

2/3

1.4/2

2/3

3860

Multi- Chip & Triple Chip Unset

Carbide Tipped - TCZ & TCT

TCZ Tooth Design

Bandsaw Blade for High Efficiency Cutting of Hard Chrome Shaft and Case Hardened or Induction Hardened Materials

- Special tooth geometry designed for hard chrome bars

- The blade has a zero degree rake angle

- Unset teeth provide a superior surface finish, long life and eliminate secondary operations

- Special grade of carbide tooth material provides maximum life and cutting performance

- High heat resistance allows high speed cutting even in large solids

TCZ tooth design is a 0° positive rake angle and is used for our unset carbide blade. It excels in difficult-to-cut allows on stable machines.

Multi-Chip Unset Carbide Tipped - TCZ

Blade Width (Inches)

1-1/4 x .042

1-1/4 x .042

1-1/2 x .050

1-1/2 x .050

Teeth per inch

2/3

3/4

2/3

3/4

Multi-Chip Unset Carbide Tipped - TCT

Blade Width (Inches)

3/4 x .035

3/4 x .035

1 x .035

1 x .035

1-1/4 x .042

1-1/4 x .042

1-1/2 x .050

1-1/2 x .050

1-1/2 x .050

2 x .063

2 x .063

2 x .063

Teeth per inch

3

3/4

3

3/4

2/3

3/4

1.4/2

2/3

3/4

1.4/2

2/3

3/4

TCT Tooth Design

Bandsaw Blade for Economical High-Efficiency Cutting of Difficult and Abrasive Materials

- Unset teeth provide a superior finish, long life, and eliminate additional finishing operations.

TCT tooth design is a 10° positive rake angle and is used for our unset carbide blade. It excels in difficult to cut alloys on stable machines.

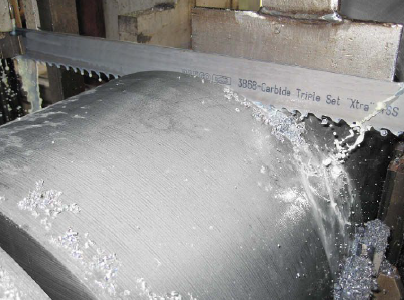

3868

Series

Carbide Triple Set TSS

TSS (Triple Set

Stainless - Honed)

Patented edge preparation (honed) eliminates the need for break in.

Designed specifically for production cutting of stainless steels.

The teeth of the 3868 are tipped with a special grade of carbide to cut the most difficult materials.

Carbide is very tough so the edges can withstand the high impact forces of bandsawing without breaking or chipping.

This triple chip tooth design has a rake angle of 10 degree and pre “run-in” at the factory. Designed to remove the need for running in on the machine allowing full speed, feed operation from the first cut in stainless steel. This is a unique and patented tooth design. not suitable for titanium applications.

Carbide will save you money by cutting material faster and lasting longer than any other bi-metal blade- that is how Bahco reduces your cost per cut.

Patented ground blade design features a triple chip blade with set teeth.

Provides clearance for good chip removal

Perfect for cutting, high nickel alloys, stainless steel, abrasive tool steel, abrasive, aerospace alloys.

Dimensions

Multi-Chip Unset Carbide Tipped - TMC

Blade Width (Inches)

1-1/4 x .042

1-1/2 x .050

1-1/2 x .050

2 x .062

2 x .062

2 x .062

2-5/8 x .062

2-5/8 x .062

2-5/8 x .062

2-5/8 x .062

3-1/8 x .062

3-1/8 x .062

Teeth per inch

2/3

1.4/2

2/3

1.4/2

2/3

1/1.25

.7/1

1.4/2

1/1.25

2/3

.7/1

1.4/2

Carbide Triple Set "Xtra" TSX

Dimensions

Multi-Chip Unset Carbide Tipped - TCT

Blade Width (Inches)

1-1/4 x .042

1-1/4 x .042

1-1/4 x .042

1-1/2 x .050

1-1/2 x .050

1-1/2 x .050

1-1/2 x .050

1-1/2 x .050

2 x .050

2 x .062

2 x .062

2 x .062

2 x .062

2 x .062

2 x .062

2-5/8 x .062

2-5/8 x .062

2-5/8 x .062

2-5/8 x .062

3-1/8 x .062

3-1/8 x .062

Teeth per inch

2

2/3

3/4

1.6

2

1.4/2

2/3

3/4

1.4/2

1.4/2

2

1.6

1/1.56

2/3

3/4

2/3

1.4/2

1/1.25

.7/1

.7/1

1.4/2

TSX (Triple Set Extra)

For high efficiency cutting of difficult and abrasive materials.

Triple set tooth design and good kerf clearance help eliminate tooth loss.

Proven to increase productivity dramatically

Greatly improved blade life

Exact same blade as TSS except not honed, perfect for applications where sharp blade is needed.

Perfect for cutting, titanium alloys, graphite alloy, aluminum with high silicon or matrix alloys.

Positive 10 degree rake angle tooth for faster cutting rates and increased productivity